Superplasticity and Advanced Microscopy Techniques

In the field of materials science, superplasticity refers to a state in which a solid crystalline material undergoes deformation far beyond its typical breaking point. This extraordinary capability allows the material to stretch and elongate significantly, often exceeding 400% of its original length during tensile deformation. Unlike conventional materials that would fracture or fail under such conditions, superplastic materials maintain their integrity, enabling them to be manipulated into complex shapes and forms.

This unique property is particularly valuable in applications where designs and lightweight structures are essential, such as in the aerospace and biomedical industries. The phenomenon of superplasticity is not merely a result of external forces but is deeply rooted in the material's internal structure and behavior, which allows it to accommodate such extensive deformation without breaking.

What Is Superplasticity?

At its core, superplasticity is the ability of a material to undergo very large plastic deformations, typically exceeding 200% elongation, without experiencing failure. This behavior is observed under specific conditions:

-

Elevated temperatures (usually above 0.5 times the melting point in Kelvin)

-

Very low strain rates

-

Fine, stable grain structures, often less than 10 microns

Instead of cracking or necking like conventional materials, superplastic alloys deform uniformly, allowing them to be shaped into intricate geometries through techniques like superplastic forming (SPF).

Common examples include:

-

Titanium alloys (e.g., Ti-6Al-4V)

-

Aluminum-lithium alloys

-

Zinc and magnesium-based alloys

These materials play pivotal roles in industries where strength-to-weight ratio and geometric complexity are critical—such as aerospace fuselages, medical stents, and fuel-efficient automotive components.

Why Microscopy Matters

Despite the large-scale deformation that superplastic metals exhibit, the real story unfolds at the micro- and nanoscale. Superplasticity is governed by:

-

Grain boundary sliding (GBS)

-

Dislocation creep

-

Dynamic recrystallization

-

Grain rotation and growth

To visualize and quantify these mechanisms, researchers turn to advanced microscopy techniques. Each method offers a unique perspective, allowing scientists to build a complete picture of how materials behave under extreme deformation.

Microscopy Techniques That Reveal Superplasticity

🔬 Optical Microscopy

Often the starting point, optical microscopy is used to examine overall grain structure before and after deformation. It helps identify whether the grain size is in the superplastic range, but lacks the resolution for deeper insights.

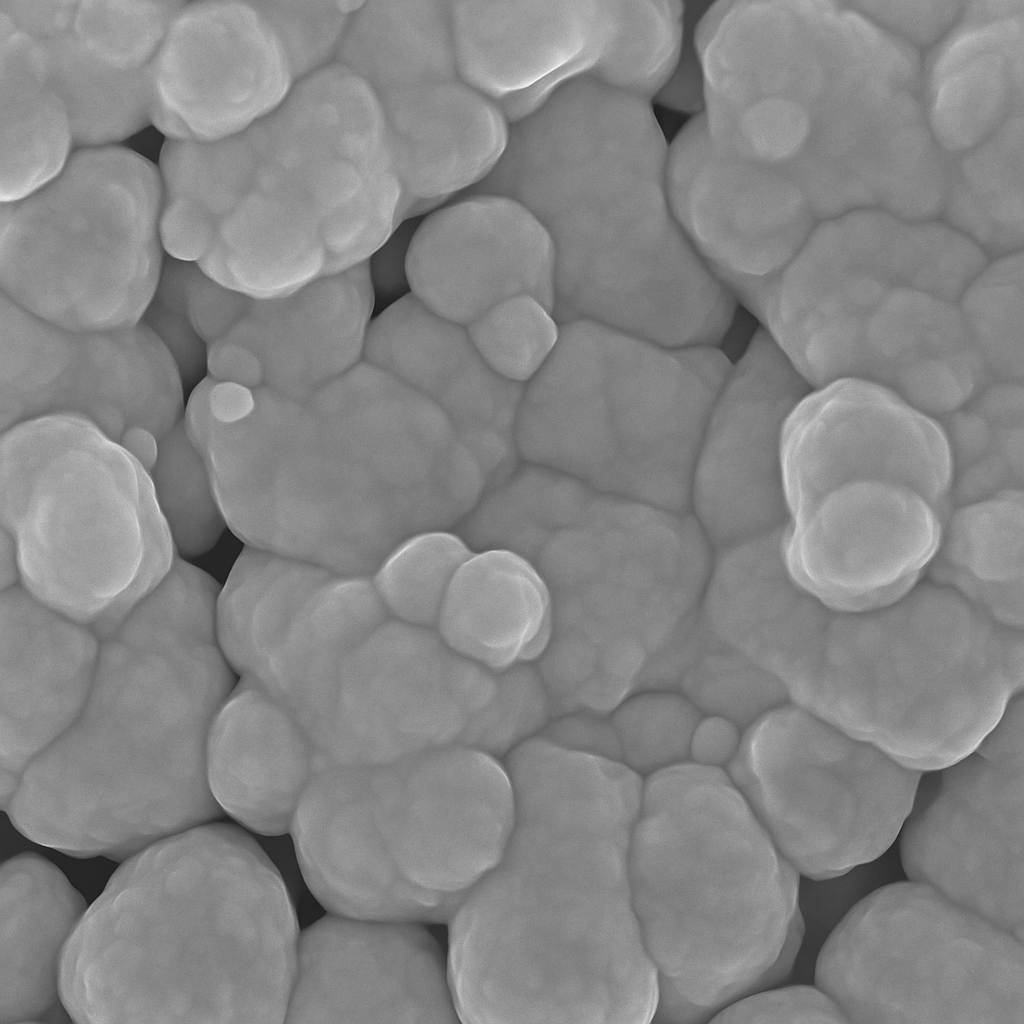

🔍 Scanning Electron Microscopy (SEM)

SEM provides high-resolution images of a material’s surface. After deformation, SEM can reveal:

-

Slip bands and voids

-

Evidence of grain boundary sliding

-

Cavitation or necking in localized areas

SEM is especially useful for fracture surface analysis and texture mapping.

🧬 Transmission Electron Microscopy (TEM)

TEM offers atomic-scale resolution, making it ideal for observing:

-

Dislocation structures

-

Sub-grain boundaries

-

Nano-twin formation

Case Studies in Action

🧪 Ti-6Al-4V Alloy: EBSD Mapping

In one study, a Ti-6Al-4V sample was superplastically deformed at 850°C. EBSD analysis revealed uniform equiaxed grains before deformation, and clear signs of grain boundary rotation and sliding afterward—hallmarks of superplastic behavior.

🧪 Zn-Al Alloys: In-situ TEM

In another experiment, researchers used in-situ TEM to deform a zinc-aluminum alloy while imaging it. They observed dislocation emission and annihilation at grain boundaries, providing direct evidence of creep-assisted sliding.

🧪 Al-Li Aerospace Alloys: 3D Microstructure

Using FIB-SEM tomography, scientists reconstructed the internal structure of an Al-Li alloy before and after SPF. The data showed how grain boundary cavitation initiated and evolved in three dimensions, informing improved process controls.

Utilization of Titanium in Aircraft Engines

In the aerospace industry, Titanium alloys such as Ti–6Al–4V are extensively utilized in a wide range of aerospace applications. This is not only due to their exceptional high-temperature strength, which allows them to withstand the extreme conditions encountered during flight, but also because a significant number of these alloys demonstrate remarkable superplastic behavior.

This unique property enables the alloys to undergo extensive deformation without breaking, making them ideal for forming complex shapes. Superplastic sheet thermoforming has emerged as a standard processing route for producing these intricate shapes, as it takes full advantage of the material's ability to stretch and mold into detailed configurations. This process is particularly beneficial in the aerospace sector, where precision and lightweight structures are crucial.

However, the inclusion of vanadium in these alloys, while enhancing their properties, also significantly increases their cost. This economic factor has driven the search for alternative superplastic titanium alloys that incorporate more affordable alloying elements. One promising candidate is the Ti-Al-Mn alloy, which not only maintains the desirable superplastic characteristics but also exhibits significant post-uniform deformation at ambient and near-ambient temperatures. This makes it a cost-effective option for aerospace applications, potentially reducing production costs while maintaining performance standards.

🧩 Application Areas

-

Fan Blades: Located at the front of the engine, fan blades are subjected to high-speed rotations and potential impacts, such as bird strikes. Ti-6Al-4V is commonly used for these components due to its high toughness and fatigue resistance.

-

Compressor Blades and Discs: In the high-pressure compressor sections, components operate at temperatures ranging from 300–500°C. Alloys like Ti-6242 and Ti-834 are selected for their superior strength and creep resistance at these elevated temperatures.Engine Casings: Titanium's lightweight and shock-absorbing properties make it suitable for engine casings, which require structural integrity while minimizing weight.

-

Stator Vanes and Rings: These components guide airflow within the engine and benefit from titanium's strength and corrosion resistance, ensuring structural stability and longevity.

📦 Representative Titanium Alloys

-

Ti-6Al-4V: The most widely used titanium alloy in aerospace, accounting for approximately 50% of titanium applications in aircraft. It offers a balanced combination of strength, toughness, and corrosion resistance.

-

Ti-6242: A near-alpha alloy with excellent mechanical strength and creep resistance up to 550°C, making it suitable for high-temperature engine components.

-

Ti-834: Developed for high-temperature applications, this alloy provides enhanced strength and stability, particularly in European aerospace engine components.