Large-Area Imaging for Tire Manufacturing Research and Surface Analysis

In the tire manufacturing industry, the performance and safety of a tire depend not only on its macro design but also on the microscopic structures hidden deep within its materials. Understanding these structures—how they wear, degrade, or behave under stress—is crucial. That’s where large-area, high-resolution microscopy and AI-powered image analysis step in.

🔍 Surface Wear Analysis: Beyond the Naked Eye

Tire treads and sidewalls are continuously exposed to mechanical stress, heat, and environmental abrasion. Over time, this leads to micro-scale scratches, cracks, and wear patterns that can compromise performance.

To monitor and quantify these changes, manufacturers rely on tools like optical microscopy, 3D profilometry, and scanning electron microscopy (SEM). However, inspecting a small patch of rubber isn’t enough. Engineers often need to study wide surface areas to identify uniform wear patterns—or more critically, locate localized defects that might signal premature failure. This is where large-area stitched microscopy becomes essential.

With AI-based analysis, vast stitched images can be automatically segmented, quantified, and compared over time or across samples—helping R&D teams move faster from insight to action.

🧪 Composite and Rubber Material Analysis: Making the Invisible Visible

Modern tires are a blend of complex materials: natural and synthetic rubber, silica, carbon black, polymer fibers, and other chemical agents. Understanding how these components are distributed within the matrix—and how well they are bonded—plays a major role in performance, durability, and manufacturing consistency.

Microscopy techniques like SEM, TEM, and AFM are used to examine filler dispersion, phase separation, and interfacial adhesion. But these properties rarely appear in neat, small samples. Instead, large stitched or multi-channel images allow scientists to map the material behavior over the entire cross-section, identifying areas of poor dispersion or agglomeration at scale.

AI-based segmentation tools help classify and quantify different phases, measure dispersion quality, and support statistical comparisons across batches.

⚙️ Crack Propagation and Fatigue Testing: Seeing the Path of Failure

Tires endure millions of stress cycles. Tiny defects can evolve into cracks—and these cracks propagate silently until they reach a critical point.

Engineers use high-resolution microscopy to study crack initiation points and track their growth. These micro-cracks often emerge from internal flaws, voids, or fiber misalignments invisible to the naked eye.

By capturing a sequence of high-magnification images and combining them into a continuous stitched view, researchers can observe how a crack evolves and interacts with the surrounding microstructure. AI can further assist in quantifying crack length, tip sharpness, and propagation angles—accelerating fatigue modeling and lifecycle prediction.

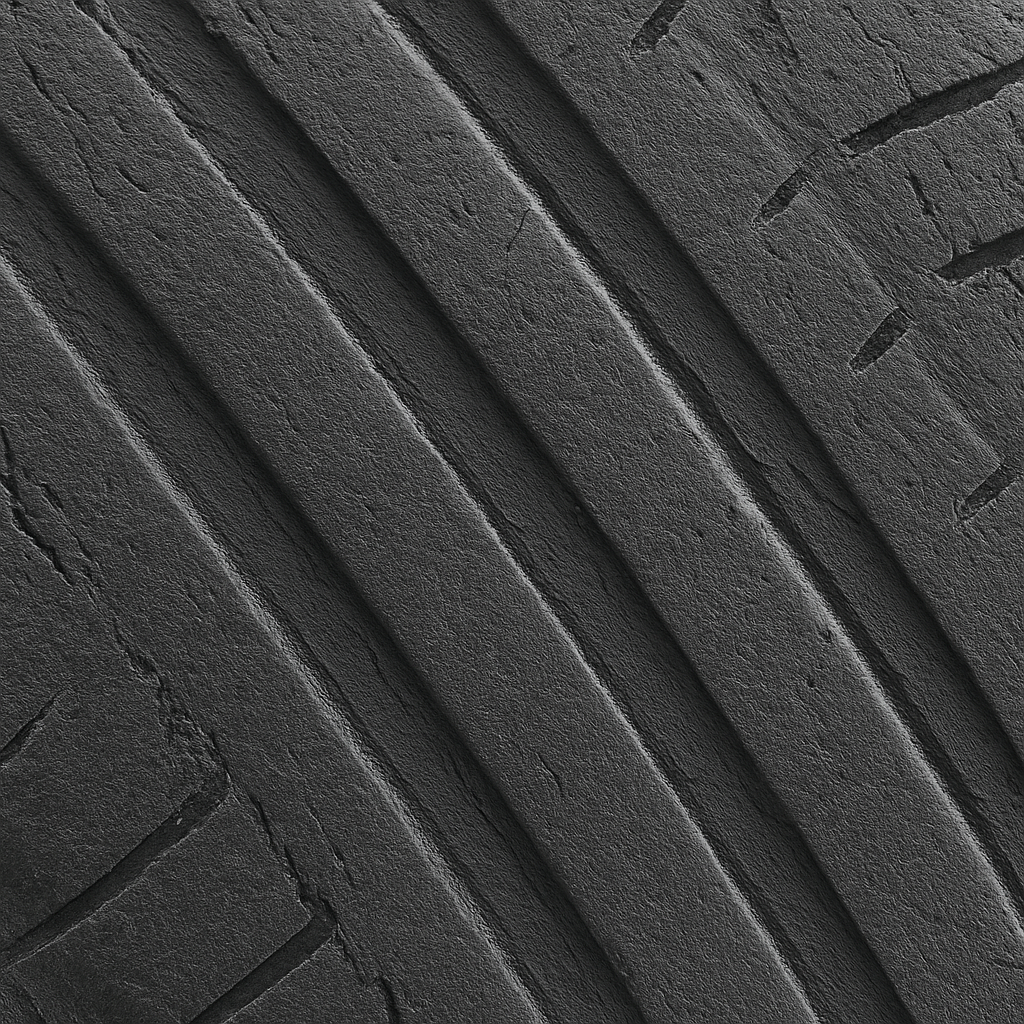

🔬 Fiber Alignment and Structural Integrity: Reinforcement Under the Microscope

Inside every tire lies a hidden structure of reinforcing fibers—nylon, rayon, polyester, or aramid—that add strength and shape retention. The orientation, spacing, and continuity of these fibers significantly affect how a tire behaves under load.

Large-area microscopy, especially through panoramic imaging, is a key tool for analyzing fiber alignment across different zones of the tire. Cross-sectional images stitched together at high magnification reveal not just how fibers are placed, but also how consistently they are embedded throughout the rubber.

AI algorithms can trace and statistically evaluate alignment, spacing, or fiber waviness—insights that would be extremely tedious or even impossible to extract manually.